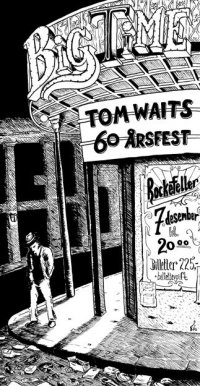

Ping hyller Tom Waits på Rockefeller

Mandag 7. desember runder vår alles Tom Waits 60 år. I den anledning trommer et kobbel norske og svenske artister sammen til storslagen feiring på Rockefeller. Som kjent er Jørgen i barselperm til nyttår, men for en kvelds skyld lar han barn være barn og tar whiskeyrøsten med på scenen igjen. Vi gleder oss!

!

slot siteleri 2024: slot siteleri – deneme veren slot siteleri

sapporo88 login

http://slotsiteleri.bid/# slot siteleri bonus veren

1вин 1win вход 1вин зеркало

pin up: пин ап – пин ап зеркало

1вин зеркало 1вин 1вин зеркало

http://pin-up.diy/# pin up казино

пин ап вход: пин ап вход – пин ап зеркало

1xbet официальный сайт: 1хбет зеркало – 1xbet

пин ап: пин ап казино – pin up казино

http://vavada.auction/# vavada online casino

пин ап вход: пин ап вход – пин ап зеркало

зеркало 1хбет: зеркало 1хбет – 1xbet

pin up: пин ап – пинап казино

http://1win.directory/# 1win вход

пин ап казино вход: пин ап казино – пин ап зеркало

пин ап: пин ап – пин ап

https://1win.directory/# 1win официальный сайт

vavada казино: казино вавада – вавада казино

vavada зеркало: вавада зеркало – vavada

http://1xbet.contact/# 1xbet

1вин: 1win зеркало – 1win зеркало

пин ап зеркало: pin up – пин ап казино

http://1win.directory/# 1win

1xbet зеркало: 1хбет – 1хбет зеркало

ile trwa egzamin na prawo jazdy

1xbet официальный сайт мобильная версия: зеркало 1хбет – зеркало 1хбет

https://1win.directory/# 1вин

http://vavada.auction/# вавада рабочее зеркало

1xbet зеркало: 1хбет зеркало – 1xbet зеркало

1win вход: 1вин официальный сайт – 1win

The Significance of Resonance Regulation Equipment in Industrial Equipment

Across manufacturing contexts, machines along with spinning equipment constitute the foundation of manufacturing. Nonetheless, one of the commonly widespread concerns which may affect the operation and lifetime exists as vibration. Oscillation might result in a series of challenges, including decreased exactness along with performance to greater deterioration, ultimately resulting in expensive interruptions along with restoration. This is where resonance control tools is critical.

The Reason Oscillation Control proves Critical

Resonance in machinery might bring about various negative effects:

Reduced Operational Performance: Exaggerated resonance may lead to misalignments and instability, minimizing the performance of such machinery. Such a scenario may result in reduced output times and elevated energy consumption.

Heightened Wear and Tear: Persistent oscillation accelerates overall erosion of mechanical parts, leading to additional servicing and an risk for unexpected failures. This not only heightens maintenance expenses but also shortens the longevity in the systems.

Security Hazards: Excessive vibration can pose considerable security risks for both the equipment and the machinery and the operators. In, extreme situations, this might lead to catastrophic machinery failure, endangering employees and causing considerable destruction to the facility.

Precision along with Quality Problems: For industries which depend on high precision, including production or space industry, vibrations could result in discrepancies in manufacturing, leading to faulty goods along with greater waste.

Economical Solutions for Vibration Management

Investing in vibration control tools proves not just a necessity but a smart decision for any business any industry that relies on machinery. We offer modern vibration control systems are designed to remove resonance within any machine or rotational systems, ensuring seamless along with efficient functioning.

One thing that distinguishes such apparatus above the rest remains its affordability. We know the value of affordability within the current market, which is why we provide high-quality vibration management solutions at prices that are reasonable.

By selecting our systems, you’re not only preserving your mechanical systems and enhancing its performance as well as investing towards the long-term success of your operations.

Conclusion

Vibration management proves to be a necessary aspect in ensuring the efficiency, security, and longevity of your machines. With our affordable oscillation control systems, it is possible to ensure your processes run smoothly, all manufactured items maintain high quality, and your workers remain safe. Don’t permit oscillation affect your machinery—invest in the appropriate systems today.

The Cruciality of Vibrations Mitigation Systems in Mechanical Systems

Inside industrial environments, machines and rotating devices act as the foundation of production. However, one of the most widespread problems which could affect their performance as well as longevity exists as vibration. Vibration may lead to a range of complications, including lowered exactness and effectiveness to heightened erosion, ultimately resulting in costly interruptions and repairs. Such a situation is when vibration management apparatus becomes vital.

The Reason Vibration Control proves Critical

Vibration in industrial equipment can bring about numerous detrimental outcomes:

Decreased Production Productivity: Excessive vibrations could result in misalignment and unbalance, decreasing the effectiveness of the devices. This can lead to slower production times and elevated energy use.

Heightened Deterioration: Constant vibrations speeds up the damage to machinery parts, causing additional upkeep and the potential of unexpected failures. This not only raises production expenses as well as decreases the longevity of the existing systems.

Safety Risks: Uncontrolled vibration might present substantial dangers to the machinery and the equipment and the operators. In, severe cases, these can bring about disastrous equipment breakdown, endangering personnel and resulting in significant destruction in the premises.

Accuracy and Quality Challenges: For industries that rely on exact measurements, for example manufacturing as well as aviation, oscillations might cause discrepancies in the manufacturing process, resulting in flawed products and increased waste.

Reasonably Priced Solutions to Vibration Control

Investing in the vibration management systems remains not merely a necessity and also a sound investment for any business any company dependent on machines. Our modern vibration mitigation tools are designed to built to reduce resonance from various machine or rotating machinery, ensuring seamless and efficient operations.

Something that sets our tools apart is its cost-effectiveness. It is recognized that the significance of cost-effectiveness within the modern competitive marketplace, and for that reason we offer high-quality vibration control solutions at prices that are reasonable.

By choosing our equipment, you’re not only securing your machinery as well as boosting its performance but also putting investment in the enduring performance of your operations.

Final Thoughts

Vibration management proves to be a vital aspect of maintaining the efficiency, safety, and longevity of your machinery. With our affordable oscillation control systems, it is possible to be certain your processes operate seamlessly, all manufactured items remain top-tier, as well as all personnel stay safe. Don’t let vibrations affect your business—make an investment in the correct apparatus today.

prawo jazdy kat b cena

mexico pharmacy cialis: percocet online no prescription pharmacy – pharmacy viagra price

online pharmacies uk: mexican pharmacy prednisone – mexican pharmacy adipex

https://pharm24on.com/# target pharmacy effexor

rx pharmacy coupons review

Doxycycline: cialis generic online pharmacy – best indian online pharmacy

https://drstore24.com/# jcm pharmacy tadacip

naltrexone india pharmacy

clobetasol propionate online pharmacy: cialis price pharmacy – spain pharmacy viagra

https://easydrugrx.com/# pharmacy rx one reviews

uk pharmacy online

usa pharmacy: amoxicillin online pharmacy no prescription – wellbutrin pharmacy online

https://drstore24.com/# Lexapro

alliance rx specialty pharmacy

https://onlineph24.com/# reliable rx pharmacy hcg

cialis online pharmacy australia

azithromycin online pharmacy no prescription: legit online pharmacy – frys pharmacy

Cialis Oral Jelly: custom rx pharmacy – ambien pharmacy price

https://easydrugrx.com/# reliable rx pharmacy coupon

dominican republic pharmacy online

Fluoxetine: disulfiram online pharmacy – Lexapro

https://easydrugrx.com/# target pharmacy bupropion

anabolic steroids online pharmacy reviews

Cozaar: indian pharmacies safe – cialis india online pharmacy